With the aim of making products that are more efficient for our customers and more sustainable for the environment, Wenco is always working on developing new solutions and innovating on the existing ones.

In the beginning, the mold maintenance and handling shop was responsible for leading this development.

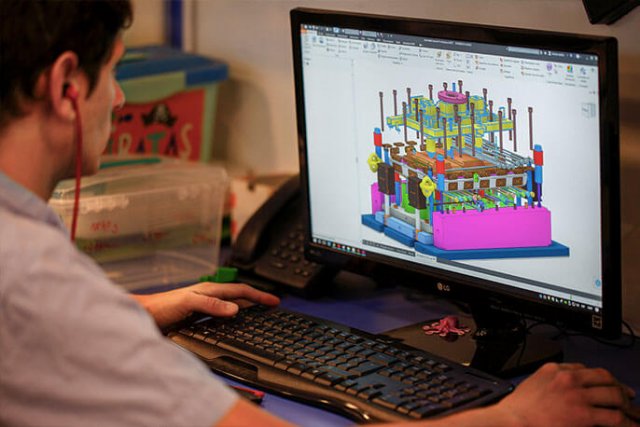

As the company grew, development was shifted to the engineering and design department, which starting in 2001 was strongly expanded and funded.

By 2020, the solutions developed by this department for the Wenco Companies have been granted 189 patents in a dozen countries.

By 2020, the solutions developed by this department for the Wenco Companies have been granted 189 patents in a dozen countries.

The best way to understand the full scope of our development and innovation work is to double click on any of these four specific cases.

Wenco has the largest and most modern mold maintenance and handling facility in Chile, and the company employs highly specialized…

See more →

In 1997 Wenco developed a bin that had a standard exterior size but which had 8% more interior capacity.

See more →

Wenco was a market pioneer in introducing blow molded pontoon platform floats that did not have to be filled with…

See more →

The Xpo crate was created for the fresh fruit export industry in order to offer a better performing alternative to…

See more →